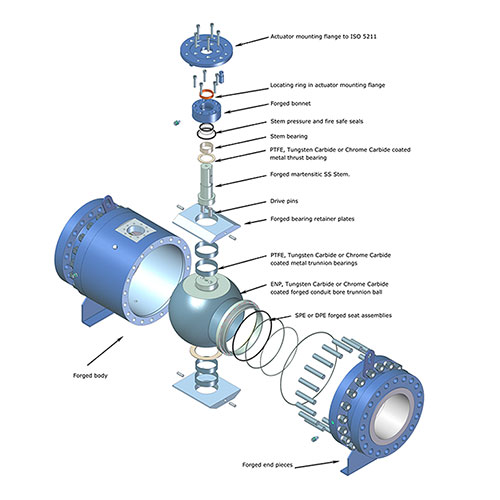

Forged 3 Piece Trunnion Ball Valves for the Oil and Gas Industry

The forged 3 piece side entry bolted body version is a proven and trusted valve design in the oil and gas industry.

It has the strength of forged components combined with serviceability, cost efficiency and reliability.

All the pressure boundary parts including the ball, stem, seat rings and bearings retainers are forged components. The ball is supported in trunnion housings in sizes up to 4″ and in bearing retainers in sizes up to 28″.

The design allows the removal of the valve from the line and the subsequent dismantling at site for maintenance.

Although RGR manufactures bare shaft valves, we have the in house expertise and experience to supply all valves with any operator design type and configuration the client may require.

Operator size selection is based on in house torque tests performed during R&D of the valves.

All valves have been tested with different bearing and seat configurations and coatings.

Our in house capability allows us to design and manufacture valve control systems required by the particular application. All systems are subject to in house FAT’s with end user approved procedures.

As a standard feature, ball valves can be supplied with the following operating devices: